View Mobile Number

admin@sspumpsindia.com

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Abrasives | Clay Slip, Titanium Dioxide, Frit, Mill Scale |

| Alcohols Acids | All Mineral and Organic Acids |

| Cement | Cement, Mortar |

| Click to view more | |

Product Details

Cosmetics

Creams, Emulsions, Detergents

Ceramics

Slip Glazes, Clay

Drilling

Mud, Grout, Lubricants

Drinks

Soft Drinks, Spirits, Beer, Wine Milk

Explosives

Suspensions of Gun Powder Explosive, Etc

Inks & Dyes

Printing Inks, Driers, Dyes, Sixes and Solvents

Foods

Liquid and Semi-solid Foods, Flavourings

Oils

Petrol, Diesel, Hydraulic and Cutting Oils, Lube Animal and Vegetables Oils and Greases Oils

Pulps

Paper, Wood Sizes Bleaches

Resins

Natural and Synthetics, Water and Solvent Based Monomeric and Polymeric Plastics

Sludge & Waste

Sewage, Effluents, Coal and Lime Slurry

Solvents

Aromatic and Allphatics, Ketones, Aldehydes, Esters and Chlorinated Hydrocarbons, De-icing Fluids

Water

All Types

Timber Preservatives

Creosote, Turpentine, Copper, Napthenate

Paint

Emulsions, Latexes, Pigments, Solvent, Resins, Thinners

Pharmaceuticals

Liquids, Creams and Compounds

Plating

Aggressive Acids, Salts, Sludge and Effluents

Rubber

Natural and Synthetic

Advantages :

- No Seal, No Leakage

- Self Priming, No need of foot valve

- Variable flow with pump.

- Can be submerged.

- Less stock of spare to be maintain.

- No Skilled person is needed to

- operate and repair pump.

- Light weight, handy in use.

- No rotation, no wear & tear, hence

- low maintenance.

- No Charging.

- Pump can run dry.

- Stops automaticlly on closing of discharge valve.

- Can handle 2 to 10 mm sized solid particles.

- Also can be used upto accuracy 3 to 5%

- No Motor, No fire.

- In short very simple and versatile pump.

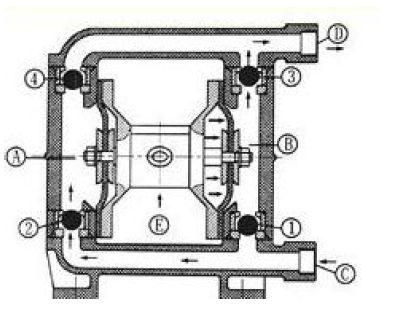

Operation Principle :

- Dry air is given as input to air valve.

- Air will push both diaphragm alternatively.

- Four ball valves will act as NRV for suction and delivery.

- As per liquid compatibility MOC of diaphragm, Valve and wet part selected.

Range

| Model | Material of Casing | Air Press in Bar | Max Soild Size in MM | Suc*Dis BSP | Flow Range in LPM |

| AODD 15 | PP, SS, PVDF, AL | 7 | 2.5 | 0.5” | 0-25 |

| AODD 25 | PP, SS, AL, PVDF | 7 | 3.4 | 1” | 0-59 |

| AODD 40 | PP, SS, AL | 7 | 5 | 1.5” | 0-137 |

| AODD 50 | PP, SS, AL | 7 | 6.5 | 2” | 0-295 |

| AODD 80 | ALUMINIUM | 7 | 10 | 3” | 0-440 |

Graph

Looking for "Air Operated Double Diaphragm Pump" ?

Piece

Explore More Products